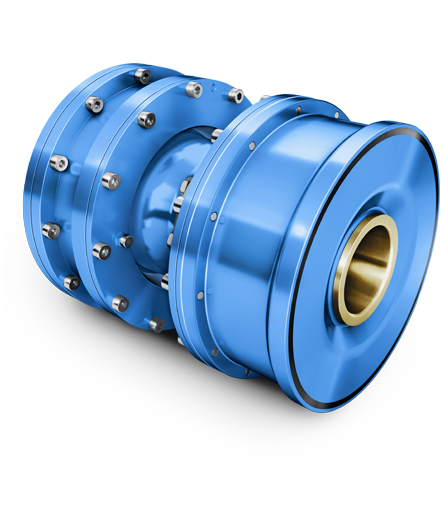

ZBG gear coupling

- Torsionally rigid curved-tooth coupling

- Nominal torque range up to TKN = 3,000 Nm

- Temperature range: from –50 °C to +55 °C

Good connections thanks to quality

Grease-lubricated FLENDER ZBG® gear couplings make the best-possible contribution to safeguarding the maximum availability of your rail vehicle. Millions of kilometers of track, icy Siberian temperatures, extreme heat, maximum starting torques and revolution speeds, extremely dusty conditions, axial or radial jolts at high speeds – whatever route you use it on, the FLENDER ZBG is always in its element.

The torsionally rigid coupling has a robust, weight-optimized design. Heavy parts are directly attached to the motor or gear unit shafts; the coupling’s inner components compensate for any operational misalignments so that only the slightest unbalanced forces and oscillations apply. The patented slip hub protects the drive system. Sealed grease chambers prevent the lubricant from escaping and eliminate the potential fire risk.

Your benefits at a glance

- Long service life and low maintenance expenses

- Maintenance-free for up to three million kilometers of vehicle travel or 12 years

- Wear-resistant and service-friendly with very long maintenance intervals

- Main inspection combined with gear unit and motor checks

- On request, initial lubricant filling can occur on delivery

- Simple and rapid relubrication using the grease nipple

- Good emergency running properties thanks to sealed grease reservoirs

- Clear load reserves, even after extremely long running times

- Optimized seal system to prevent dust from penetrating

- Reliable running if the chassis is icy and at temperatures well below zero

- Heat-resistant, even in extreme conditions

Made in Germany, worldwide in use

- Metros

- High-speed trains

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services