Rolling Mills

Roller presses

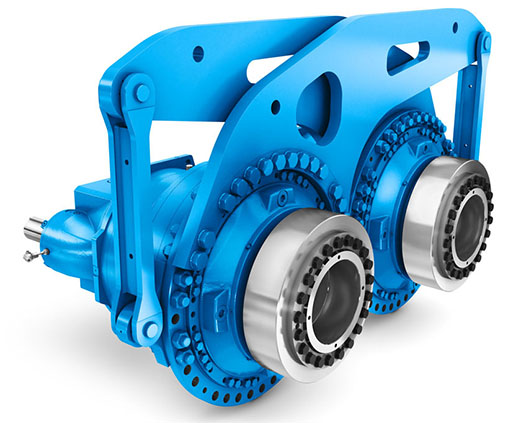

Extremely strong. Extremely compact. Extremely stressable.

Efficiency and reliability for rolling mills and roller presses

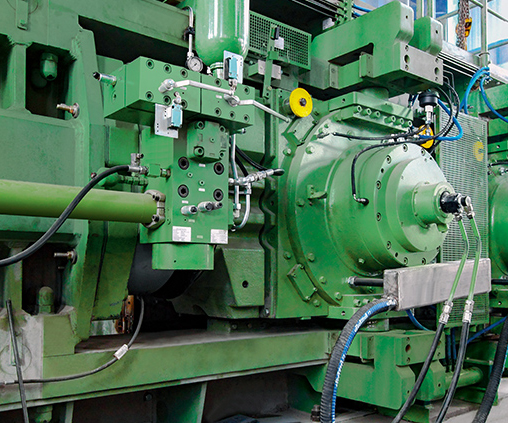

Uneven loads, extreme axial and radial forces, high dust generation – the grinding of iron ore, limestone and clinker is marked by harsh working conditions. High-pressure rolling mills and rotary kilns are particularly demanding applications that call for maximum performance and reliability from the drive systems. The grinding process must be guaranteed energy-efficient and reliable at the same time. Our planetary gear units have been used as drives in roller presses and rolling mills for decades. The product portfolio during that time has been continuously optimised and expanded. Today our gear units are the perfect solution for rolling mills and roller presses. Their low weight reduces loads on gear units and machines. High radial and axial additional forces exerted by universal-joint shafts and floating-roller acceleration are absorbed by the standard bearing system. The high overload capacity here ensures operational reliability and stabilises your process.

Your benefits at a glance

- Up to 40% higher torque for the same installation dimensions compared to the PLANUREX 2 roller press drive and competitors products

- Maximization of plant availability through optionally integrated Flender measuring systems

- Low operating costs and high efficiency due to optimized gear geometries and the high level of manufacturing quality

- Precise adjustment of the output speed possible due to a stepless range of transmission ratios

- Shortest delivery times with a standardized roller press solution

- Smallest achievable roller distances thanks to top performance in a small installation space

- Long service life through application-oriented design and top-class quality

- High-performance input shaft bearings to absorb additional external forces emanating from the universal joint shaft and with an optional protective device for load-free rotation over a short period of time

Applications

- Cement industry

- Mines

Technical Data

| Rated Torque | 480,000 – 5,450,000 Nm |

| Transmission | i=1:45 – 1:110 |

| Power | up to 7,000 kW |

| Sizes | 17 |

Information material

Press information

New planetary gear units for roller presses offer the best power density in the market

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services