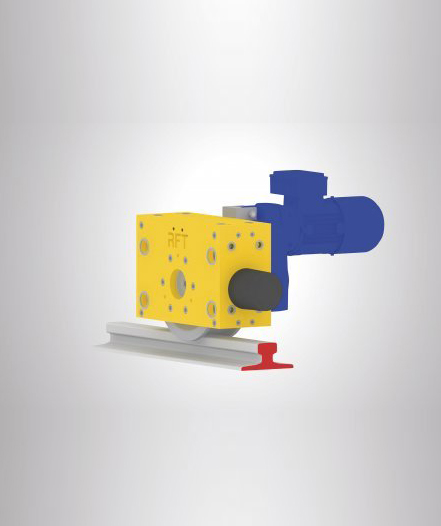

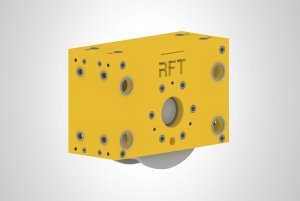

Wheel block system type RRB

Application areas:

- Crane systems

- Offshore / Ship

- Steel industry

- Mining / Material handling

- Railbound hall roofs / gates

- Special machine construction

- Mechanical / Plant engineering

Product type:

- Wheel block system type RRB

Product description

RFT wheel block systems with integrated damping unit to reduce bearing impacts / axial impact reduction!

- Flexible wheel block system

- Several connection dimensions

- Compatible with shaftmounting gear unit

- For wheel sizes from Ø160 up to Ø710 (other sizes on request)

- Made from solid material / No Castings

- With or without wheel flange

- As Idler wheels or drive wheels

- Wheel block system used as synchro travel system

- MADE IN GERMANY, own production

Highest quality and long economic life-time!

Recommendation: Each wheel without flange should be guided by a guide roller system.

Particulary suitable guide roller systems with integrated damping pads to reduce impacts resulting from rail misalignments.

Technical benefits

All RFT wheel block systems will be manufactured exclusively in Wetter, Germany. The integrated RFT damping unit protects the spherical roller bearings against unwanted axial impacts (resulted e.g. from rail misalignment) and therefore increases the lifetime.

MADE IN GERMANY.

Integrated damping unit to reduce axial impacts

Wheels made from solid material

Exclusively homogeneous material

NO casting / moulded casting

Avoidance of cracking

Optimal bearings

Long service life

Wheels without flange do not wear out the sides of the rail head and can be guided optimally via guide roller systems.

- Reduction of impact forces

- Bearings will not be destroyed due to impacts

Even transverse forces within a system due to different speeds can be avoided if wheels will be guided optimally.

Gallery

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services