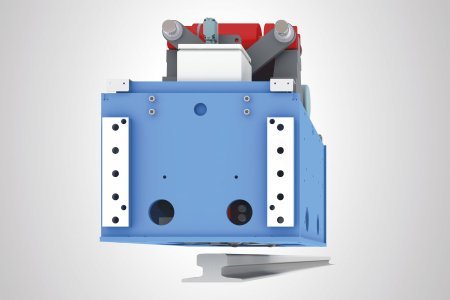

VZFH-HVZ / Spring force – Hydraulical, with lifting function

Storm brake / rail clamp type VZFH-HVZ, with lifting and positioning function

Application areas:

- Crane systems

- Offshore / Ship

- Steel industry

- Railbound hall roofs / gates

Product type:

- VZFH-HVZ / Spring force – hydraulical, with lifting function

Patent:

- Positionierungsfunktion / Zangen-Senksystem

Product description

Storm brake / rail clamp with integrated lifting and positioning function. Patent pending.

- With integrated lifting function

- No contact to the rail during crane travel / Therefore no wear on clamping jaws and guide rollers during crane travel

- No guide rollers for guidance the clamp on the rail during crane travel

- Lateral positioning function for lowering the clamp system -(patented pending system)

- Particularly suitable for fast moving crane systems

- Particularly suitable for transverse travels / cross-runs

- Restraining / holding forces up to 640 kN per clamp

- Self acting in case of power failure

- MADE IN GERMANY

Functional principle

- Closing by spring force with toggle lever system – adjustable by throttle

- Opening by hydraulic-cylinder (Hydraulic power unit is integrated)

- Hand pump for emergency operation (manual) is supplied (standard)

- Automatically closing function in case of power failure

- No loss of restraining / holding force due to toggle lever transmission resulting from e.g. wear of clamping jaws (permissible measure)

- Limit switch position control system “Clamp open”, “Clamp close” and alarm signal “worn clamp jaws”

- Position control switch for “Clamp is in lifting position / Crane travel is possible

- Vertical movement compensation of + 40 mm up to – 20 mm

- Lateral compensation for rail misalignment of ± 25 mm with integrated lateral guidance system during lowering

- During crane operation all parts of the clamp are positioned above the rail system / Therefore no wear of any components during crane operation

- Guide rollers for guide the storm brake on the rail as used at standard type VZFH will not be integrated into type VZFH-HVZ (wear reduction, reduced maintenance and follow-up costs)

Technical benefits

- Particularly suitable of fast moving crane systems

(over 300 m/min) - Strongly reduced maintenance / follow-up costs

- No contact to the rail during crane travel

- No loss of restraining / holding force due to toggle lever transmission (resulting e.g. wear of clamping jaws)

{{ Reparatur }}

Additional to own brand production, RFT is specialized in repairing storm brakes / rail clamps of other brands due to in-house production flexibility.

Rail clamps show wear due to the fact that they are in use over many years, which means they no longer have the neccessary safety levels required.

- Functional analysis oft he rail clamp / storm brake

- Renewal of the clamping jaws

- Renewal of the bushes

- Renewal of the axis

- New painting

- In case of extreme steel wear the construction will be overhauled and restored into the original condition

- High-grade 2-component paint

In specific situations, the RFT can provide a storm brake as a ring exchange.Therefore the Intralogistics and safety operates smoothly and is undisturbed.

Please indicate your existing rail clamp type.

Options

- Special flange mounting

- Special construction

- Special painting of housing (Please specify RAL color)

Gallery

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services