Pneumatic Clutches

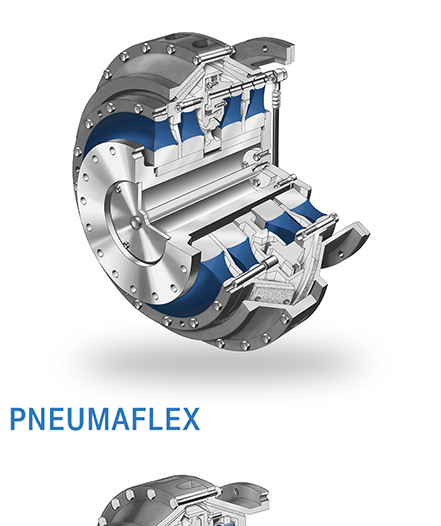

PNEUMAFLEX

- Clutch torques of up to 304 kNm

- Pneumatic switchable

- Reliably interrupts or establishes the flow of power

Experience since 1964 – proven reliability

The PNEUMAFLEX clutch is a combination unit comprising a double conical friction clutch and highly elastic coupling. The clutch components comprise two inner friction cones which are pressed against two outer friction conical faces via the pneumatically actuated clutch cylinder.

The elastic part comprises rubber elements arranged in parallel which are completely optimized enhancing the coupling’s reliability and performance significantly.

Due to the high torsional flexibility of the rubber elements, PNEUMAFLEX KA clutches shift resonance (torsional vibration) between the natural frequencies of the system and the exciting frequencies of the driving and driven machines across the operational speed range. Due to their high damping qualities, they also reduce the residual vibration amplitude and thus protect the valuable assets.

Moreover, the clutch compensates center mismatch, in both axial as well as angular misalignment, for connecting machinery elements (engines, gearboxes, generators, etc.) within a predetermined tolerance range. Additionally, the rubber elements effectively isolate structure-borne noise.

Your benefits at a glance

- Combination of a dry friction clutch and highly elastic coupling without short-lived idle bearing system

- Complete separation of primary and secondary sides

- Backlash-free, no wear of components subject to backlash

- Smooth and easily controllable engaging operation

- Protects the propulsion system against overloads if a slip monitoring unit is used

- Clutches of type KAP can be vertically removed

PNEUMASTAR

- Torsionally stiff clutch torques up to 1400 kNm

- Pneumatic switchable

Smooth engagement

The PNEUMASTAR is a torsionally stiff, double-cone, friction clutch. The clutch components consist of two inner and two outer friction cones which are pneumatically pressed against the outer tapered friction faces via a pneumatically operated clutching cylinder. Rubber sleeve springs form the torsionally stiff portion of the clutch.

Due to the high resilience of the rubber sleeve springs, the PNEUMASTAR clutch is capable of effectively compensating radial, axial and angular misalignments within predetermined limits. Moreover, as the clutching components are moved over the rubber sleeve springs during the actuation of the clutch, wear through axial sliding movement between the various contacting parts is avoided.

Pneumatic operation of the clutch enables speedy and precise manoeuvring, which is a prerequisite for use in the marine application.

Your benefits at a glance

- For stiff, but interchangeable connections

- Backlash-free, no wear to components subject to backlash

- Smooth and easily controllable engaging operation

- A range of clutch types are available with different connections

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services