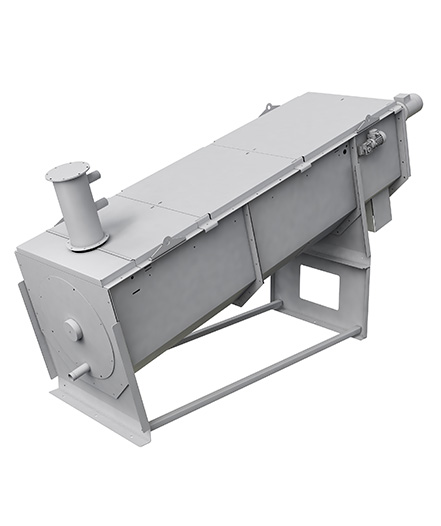

Sludge screw press

The SD – SLUDGE SCREW PRESS is was designed to dewater the sludge coming from municipal and industrial process to obtain a result in term of dryness more than 20%.(from 18 to 25%).

The dewatered sludge is pushed by the conveying screw into the discharge chamber, during this phase, the flocculated sludge loses a certain quantity of water and before the outlet, thanks to the adjustable counterweight, provides to dewater the sludge to obtain the best performance.

The water comes out from a wedge wire section drum filter present all around the screw.

The filter maintain the maximum of efficiency thanks to the integrated motorized washing system that with an electric motor of 0,09 Kw provides to wash and consequently to clean the filter for all the external surface.

The range is composed by the Sludge screw press SD– SLUDGE SCREW and SDS – SLUDGE SCREW THICKENER.

To obtain a better performance in term of sludge dewatering, the equipment can be installed in sequence: SDS sludge screw thickener to process the sludge until 6% dryness and SD sludge screw press to reach a dryness from 18 to 25%.

The sludge must be always conditioned with polyelectrolyte in order to obtain the correct flocculation before being processed with SD and/or SDS.

Both equipment SD and SDS work with low energy consumption and low rotation speed. Consequently also the wear of the components is very limited.

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services