DX at a glance

Sensors, diagnostics, services

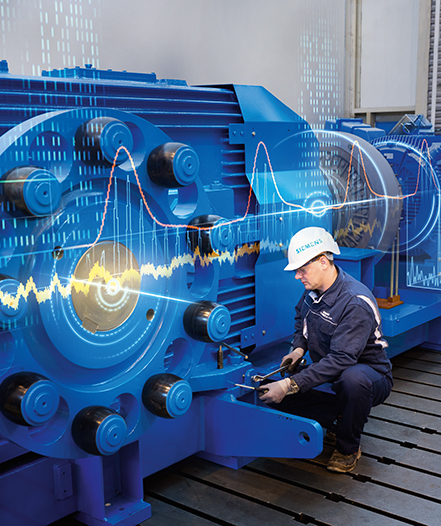

Ensuring process stability requires condition-based maintenance of the drive train. With DIAGNOSTEX®, sensors on our gear units measure deviations from the target state. These can be analyzed and evaluated for the purpose of maximizing plant availability.

DIAGNOSTEX marks an important step into the digital future of mechanical drive technology. With the help of DIAGNOSTEX, the gear unit identifies and communicates any deviations during operation, thereby initiating highly precise early damage detection by our experts. The “digital gear unit” opens up new possibilities for predictive maintenance: The necessary measures can be taken in good time and the planning of our services improved. In conjunction with optimized spare-part management, life cycle costs are significantly reduced and longer gear unit downtimes virtually eliminated.

Benefit from:

- Globally available mobile measurement and diagnostic services from local service teams

- Remote diagnostic services for standard and application-specific gear units

- Highest reliability of results due to comprehensive technology and product knowledge as well as the industry expertise of the diagnostics engineers

- Gear unit service direct from the manufacturer

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services