DX2000 & DX4000

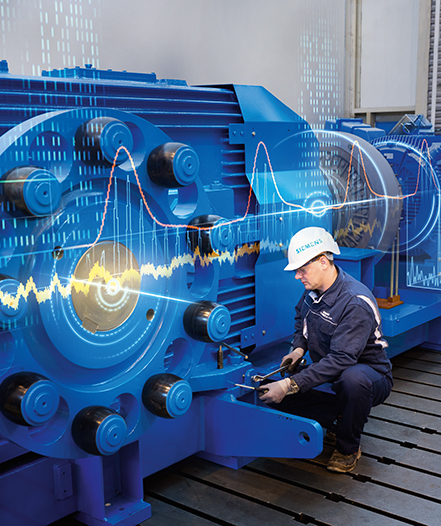

With online condition monitoring, we offer you a diagnostics instrument that is precisely tailored to your needs. Our remote diagnostic services allow condition-based maintenance of your standard and application-specific gear units. The diagnostics know-how of our gear unit experts, combined with the DIAGNOSTEX 2000 and DIAGNOSTEX 4000 hardware, represent a decisive step toward nonstop plant availability. Both remote service products offer you online data collection and recording as well as transmission of the measured data to our Remote Expert Center via secure data links.

DX2000 is the DIAGNOSTEX solution for complex gear units, e.g. for single- and double-screw extruders, pinion drives or ball mills.

Monitor up to ten gear units with only a single industrial PC and achieve cost savings up to 50%.

DX4000 is intended for gear units in demanding applications such as cranes, vertical mills and roller presses with planetary stages, and many others. DX4000 is also the right choice for monitoring of complex drive trains.

With both remote solutions, you benefit from:

- Qualified data evaluation and diagnostics by competent experts

- Specific recommendations for action as well as early warnings in the event of a fault

- Ability to schedule repairs

Reference Flender CM

Technote Vibration Sensor Technology

Brochure Flender CM

Flyer Flender CM

Overview Flender CM

Drive & Automation

Drive & Automation  Industrial Applications

Industrial Applications  Water & Waste Water

Water & Waste Water  Services

Services